CASE STUDY: University of New Hampshire Stormwater Center

1. Background

Triverus’ high-efficiency surface cleaning technology has the ability to remove critical stormwater pollutants from impervious surfaces and restore the functionality of pervious/porous surfaces. In 2019, an independent third party, the University of New Hampshire

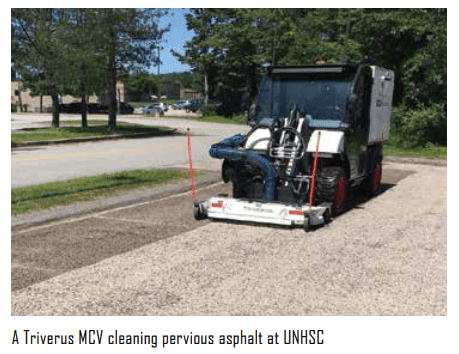

Stormwater Center (UNHSC), sought to quantify the capabilities of Triverus’ cleaning technology. A series of surface infiltration tests were conducted on various pervious pavements located on the UNH campus. These tests were performed using ASTN C1701 Standard Test Method for Infiltration Rate of In Place Pervious Concrete. This test is the industry standard for measuring pervious surface performance. Measurements were taken prior to and following cleaning with a Triverus Municipal Cleaning Vehicle (MCV), a commercially available cleaning vehicle that integrates Triverus 3800 PSI spray cleaning and recovery technology onto a Bobcat® Toolcat™ all-wheel steer carrier. Two locations were identified for detailed testing: the West Edge porous asphalt lot and the Elliot Alumni Center porous asphalt lot. Both locations were on the UNH campus in Durham, New Hampshire.

2. Testing Locations

The West Edge Porous Asphalt Lot

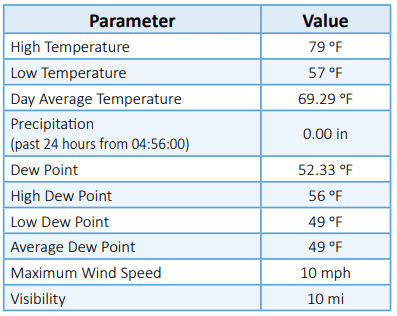

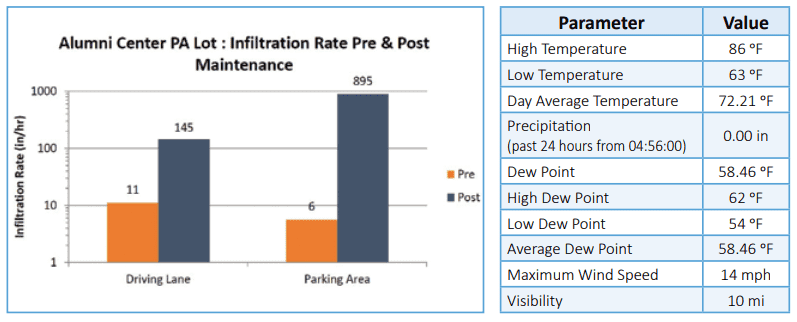

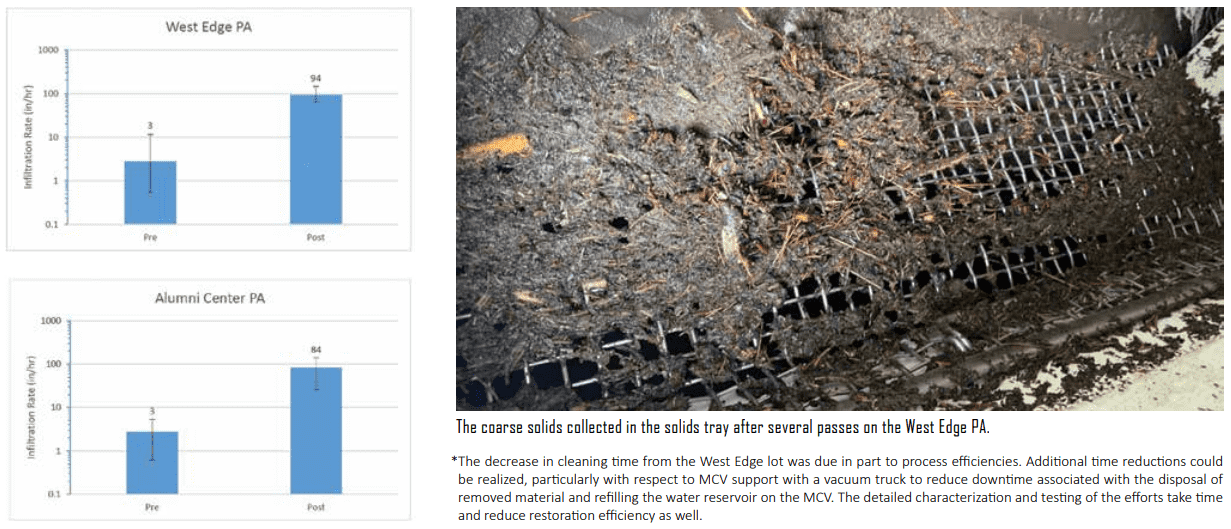

Built in 2005, the West Edge porous asphalt lot was 14 years old at the time of testing and received maintenance for at least the first five years of operation. Since 2010, minimal studies and maintenance had taken place. The area is approximately 5,000 square feet in size and had an average pre-cleaning infiltration rate of 3 in./hr. Due to the variability of the testing method, any permeable pavement with a surface infiltration rate less than 10 in./hr. is considered failed from a hydraulic perspective. The West Edge lot was cleaned on July 8th, 2019. Climate statistics for Durham, New Hampshire during testing are to the left.

Alumni Center Porous Asphalt Parking Lot

Built in 2012, the Alumni Center porous asphalt lot was seven years old at the time of testing and received maintenance for at least the first two years of operation. Since then, it was unclear how much maintenance was performed or if the maintenance was effective. From the very low precleaning infiltration rate, it appeared no maintenance had occurred since 2014. In 2015, a small test area of approximately 200 square feet in a parking spot and 200 square feet in a driving lane was conducted to assess restoration potential. The cleaning was conducted by UNHSC staff and consisted of low angle power washing into a vacuum. The overall restoration work took two staff approximately two hours per location. The experiment demonstrated the restoration potential of the technology and the need for advanced cleaning technology; at just over 50,000 square feet, the effort using staff and handwork was not insignificant (~125 hours for two staff). The Alumni Center lot was cleaned on July 10th, 2019. Climate statistics for Durham, New Hampshire during testing are below. The infiltration results from this testing are shown below.

3. Cleaning and Testing

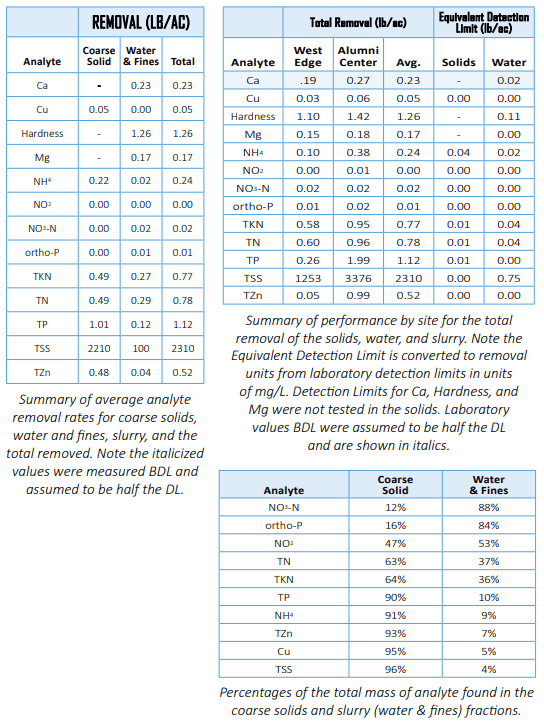

During cleaning at both sites, material was removed from the pervious surfaces by the Triverus MCV and was separated and saved for testing. The water used and recovered by the MCV during the cleaning process was also saved for testing. The coarse solids were weighed and samples collected for laboratory analysis. Grab samples of the water slurry were taken and sent as a composite sample for laboratory analysis. The restoration process was inevitably longer and more time-intensive than typical routine maintenance, but resulted in a great performance increase. The average post-cleaning infiltration rate for the West Edge lot was 94 in./hr. This is considered functional and effectively restored. The cleaning took approximately 6 hours, and 150 lbs. of coarse sediment were removed from the area. The average post-cleaning rate for the Alumni Center lot was 84 in./hr. This is considered functional and effectively restored. The cleaning took approximately 4 hours, and 350 lbs. of coarse sediment were removed from the area*.

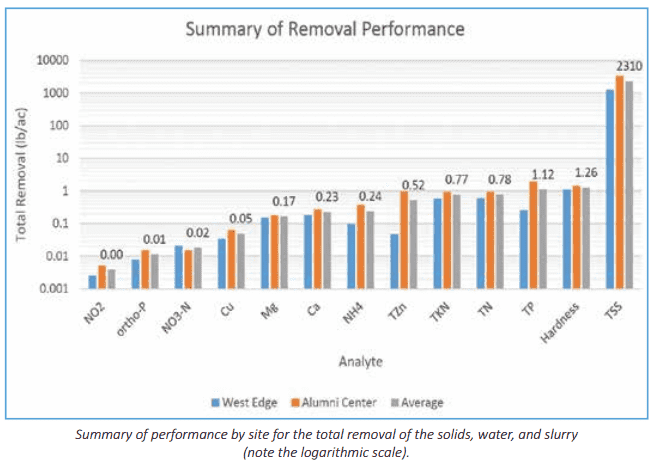

4. Results

Overall, the restoration effort was extremely successful. UNHSC’s research supports further exploration of restoration activities followed by more routine operation and maintenance such as vacuum sweeping twice per year. This data also reveals some significant differences in the pollutant partitioning between the liquid and solid fractions of the removed materials. It underscores the importance, particularly in nitrogen sensitive areas, of properly treating the removed waste materials. Learn more about this case study in the Triverus Cleaning Technology Demonstration Report by the University of New Hampshire Stormwater Center.