Pervious Pavement Maintenance For Your Community

- Pervious pavement is a specialized type of pavement that allows water to pass and filter directly through its porous structure. This reduces the water runoff from a site, allows groundwater recharge and limits the surface’s contribution to stormwater. Pervious pavement includes pervious concrete, asphalt, and interlocking concrete pavers.

- Properly maintaining pervious pavement will result in optimal performance, an operable infiltration rate, increased safety, reduced overall costs, and can prevent the need for total restoration. When needed, cleaning is performed by sweeping, vacuuming, and wet vacuuming to remove accumulated deposits. Each facility or project will have its own unique maintenance plan and schedule.

- Pervious pavement is designed to allow stormwater to filter through its surface where it then passes through soil and removes pollutants. This reduces these pollutants from entering storm drains, streams and lakes. However, pervious/porous surfaces can accumulate solids where the surface will no longer percolate as designed.

- Triverus’ pervious pavement maintenance services will ensure your surfaces are functioning as designed, preventing stormwater pollution and potential damage to your property.

- Pervious pavement maintenance is performed with the Triverus Municipal Cleaning Vehicle (MCV), a versatile and highly-efficient machine featuring a 60-inch wide cleaning deck, the widest available in this class of cleaner and the most productive in the industry.

REQUEST A QUOTE TODAY!

How Does Pervious Pavement Fail?

Foreign material and organic deposits such as leaves, dust, and pine needles accumulate on pervious pavement. “Macro-plugging” forms a blocking layer on top of the pavement’s porous structure, preventing water from penetrating the surface. Furthermore, if these organic deposits are not removed regularly, they begin to degrade and begin to plug below the pervious pavement’s surface. This process limits the functionality of the pervious pavement, leading to increased water runoff, less groundwater recharge, and more contribution to stormwater.

According to the State of Washington’s Industrial Stormwater General Permit Coverage, “Uncontrolled industrial storm water runoff discharges oil, grease, silt, and toxic substances into our waterways. Even small concentrations of polluted runoff are bad for fish and other aquatic life. Copper and zinc, which are commonly found in industrial runoff, are harmful to salmon and other aquatic life, even at relatively low concentrations”

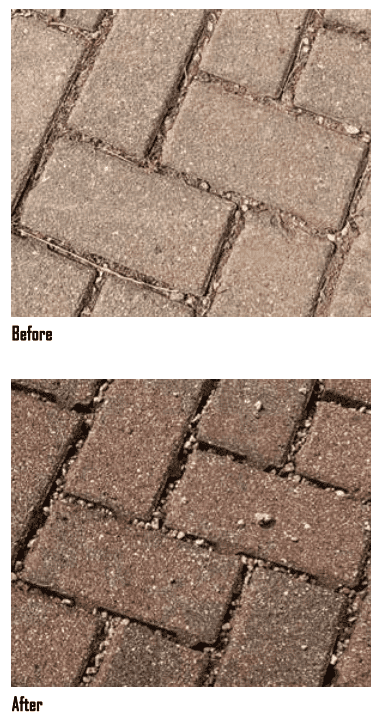

In the Before photo to the left, organic deposits are clearly visible on top of the interlocking pervious pavers and aggregate. In the After photo, the pavers have been swept and cleaned, restoring the functional permeability and leaving behind only the aggregate between the pavers. All types of pervious pavement must be cleaned to maintain permeability. Routine inspection of your pervious surfaces will allow you to monitor any buildup and assess performance.

Common Misconceptions About Maintaining Pervious Pavement

Pervious Surface Inspection

ISSUE: ORGANIC DEPOSITS

Organic deposits such as leaves, pine cones, and pine needles, collecting on pervious surfaces is normal.

REMEDY:

Consistent, immediate cleaning will help prevent the need for deep cleaning or full restoration

Cleaning with a blower (leaf blower or similar equipment),

truck-sweeping, dry vacuuming, and/or vacuum sweeper fitted with water jets.

ISSUE: FICTION AND FACT REGARDING PERVIOUS PAVEMENT

| Fiction | Fact |

| Pervious parking lots, sidewalks, or other areas can be maintained just like a conventional non-pervious surface. | To perform properly, pervious pavement requires specific maintenance that differs from conventional maintenance. |

| It is possible for pervious pavement to be so clogged, replacement is the only way to restore percolation functionality. | Almost all intact pervious surfaces can be restored to percolation functionality. |

| Routine maintenance of pervious pavement is expensive. | Routine maintenance is affordable and is much less expensive than total restoration. |

| Maintenance of pervious pavement is time intensive. | Routine maintenance can be performed quickly, with little down-time. Routine maintenance ultimately takes much less time than total restoration or replacement. |

| Pervious pavement can’t be maintained in freezing temperatures. | Pervious pavement can be maintained and will perform in freezing temperatures. They do have to be cleared of snow and ice differently than conventional surfaces. |

| Pervious pavement clogs from the bottom up. | Pervious pavement clogs from the top down. Organic and inorganic deposits break down on the surface and clog the permeable structure’s voids. |

ISSUE: LANDSCAPING RUNOFF

- Maintain upland and adjacent grassy areas

- Seed upland and adjacent bare areas

- Excessive water flow carrying debris toward the pavement should be diverted

- Minimize “Track on/track off” deposits

What To Look For

Issue: Spalling

Spalling is caused by winter salt application leading to thawing and refreezing underneath the surface. This causes the surface to pop out, peel off, or flake off.

Remedy:

- Repair

- Limit or stop use of salt in winter months

- Initiate deep cleaning protocol prior to snowfall

and cold weather

Issue: Moss Growth

Moss growth is caused by clogged pavement pores.

Remedy:

- Remove organic and inorganic deposits by aggressive pressure washing and vacuuming

- Apply baking soda to the surface and vacuum within one to two weeks. Additionally, moss growth can be controlled with applications of limewater

Issue: Puddling

Puddling is caused by clogged pavement pores, which in turn

limits the permeability of the surface.

Remedy:

- Test with perking process

- Remove organic and inorganic deposits by aggressive pressure washing and vacuuming

REQUEST A QUOTE TODAY!

Frequently Asked Questions:

- What happens to the pollutants picked up during pervious pavement cleaning?

Unlike conventional street sweepers that only apply enough energy to move loose, superficial material, the Triverus high pressure wash system will simultaneously lift, recover, and contain all fine solids and pollutants. Our technology recovers what others leave behind. These materials should be disposed of in the same way as the material recovered by street sweepers.

- How does Triverus technology improve the lifespan of pervious maintenance?

Pervious pavement clogs from the top down as organic and inorganic deposits physically break down on the surface. Gravity and water transport this material into the voids in the pervious surface and gradually clog them. Routine, seasonal maintenance extends the time between or can eliminate the need for total restoration.

- How does Triverus technology reduce Stormwater pollution?

Unlike conventional street sweepers that only apply enough energy to move loose, superficial material, the Triverus high pressure wash system will simultaneously life, recover, and contain all fine solids and pollutants, including those adhered to the surface. These can and generally do contain oil and gas, copper, tire wear residue (including the tire preservative 6PPD), zinc and phosphates.

- Can pervious pavement and concrete be maintained in very cold/freezing climates?

Yes, but because of the use of water only in the cleaning process, the maintenance should take place when temperatures are above freezing. Pervious pavements are often damaged AFTER clogging occurs because water is not allowed to follow its intended drainage path through the pervious surface. If clogging causes water to loiter in the pavement’s upper layers, the expansion of the trapped water in any freeze-thaw cycle will ravel the surface of both pervious concrete and pervious asphalt surfaces.

Preventing saturation of pervious pavement and concrete leading up to periods of very cold/freezing temperatures is key to maintenance and longevity. Cold, dry winter climates require no unique precautions. Climates with freeze/thaw cycles will generally not lead to full saturation and freezing, and thus does not require unique maintenance. Climates with hard wet winters require careful surface preparation before and after winter to ensure permeability is maintained.

- What is spalling?

Spalling happens when winter salt applications leads to thawing and refreezing under the pervious pavement surface causing the surface to ravel or peel or flake off. When maintained properly, Salt applications should not be needed. Deep cleaning prior to freezing/cold weather is important. If spalling occurs, repair will be necessary to avoid further damage to the surface.

- Why does Moss grow on pervious pavement?

Moss takes advantage of accumulated solids in a wet environment. Temperate areas in which rainfall is plentiful are particularly vulnerable to the growth of moss in the clogged upper pores of pervious asphalt, pervious concrete, and pervious pavers. In addition to contributing to further clogging of the pervious surface, moss presents an extreme slip hazard for those geographical and climactic areas like the Pacific Northwest where it is common. Removing the solids from the pervious surface is the cure for the growth of moss.

Moss grows when the pervious pavement surface remains wet. The surface remains wet because the pores are clogged and cannot drain properly. Remediation recommendation includes aggressive pressure washing and vacuuming to remove organic and inorganic matter followed by limewater applications.

- Why does pervious pavement fail to accomplish its goal of decreasing storm water runoff?

Pervious pavement and similar products are designed to allow water to percolate through the surface vs. running off the surface. If the surface pores are clogged, then runoff will occur, leading to less groundwater recharge and more pollutants in stormwater.

REQUEST A QUOTE TODAY!