The fact is that the percolation rates of pervious surfaces will decrease over time and finally clog if not properly tended to. So, what will we 1) pick up when we clean it? And 2) How do we dispose of what we pick up?

What Makes Pervious Pavement So Dirty?

The top 3/8″ to 1/2″ of pervious surfaces contain lodged organic and inorganic materials. High volumes of fine solids will be suspended in the water used to dislodge the material, which will then be transported back to the recovery tank. This will include organic and inorganic material. A lot of fine solids will be suspended in the water used to dislodge the material and transport it back to the recovery tank.

The recovered material will include anything and everything that has settled on top of your hard surface, too. This includes but is not limited to organics, phosphates, heavy metals, oil and gas and tire particulate from car traffic.

What Do I Do With That Stuff?

Plan to treat the recovered material like you do the debris recovered from your catch basins.

Pervious Cleaning at an Amtrak facility. Anything and everything has accumulated in and on this pervious surface.

Close up view of the Amtrak facility’s pervious asphalt. The pervious surface clogging goo seen on the left (not yet pressure washed) is pollutant rich. Get it out of your storm stream and into your treatment stream.

Contain and transport the slurry generated by the cleaning process. Best overall results are achieved by means of a high-pressure wash with simultaneous vacuum recovery system as found on the Triverus MCV. Full of fines and pollutants, this material should be hauled to your decant facility for treatment.

What’s the Difference Between Dirt on Pervious Surfaces and Non-Pervious Surfaces?

It stands to reason that both your pervious pavement and your non-pervious pavement will accumulate fine solids and pollutants from ambient sources. The only difference is that when it rains, the pollutants and solids on a non-pervious surface are not trapped in place like the material that gathers sub-surface in pervious pavements.

A high-pressure wash system with simultaneous recovery will lift and contain solids and pollutants from any hard surface. A conventional street sweeper only applies enough energy to the surface to move superficial, loose material. Adhered pollutants and those that have moved subsurface into the pervious pavement are beyond the job description of a conventional street sweeper regardless of vacuum recovery or regenerative air. Once wet, fine solids and pollutants will adhere to the surface and can only be moved by a soaking rain or high-pressure water wash.

High-pressure washing with simultaneous recovery of both pervious and non-pervious surfaces yields the added benefits of enhanced safety as the pavement markings become more visible

Pollutant Recovery from Pervious Pavement and Other Surfaces

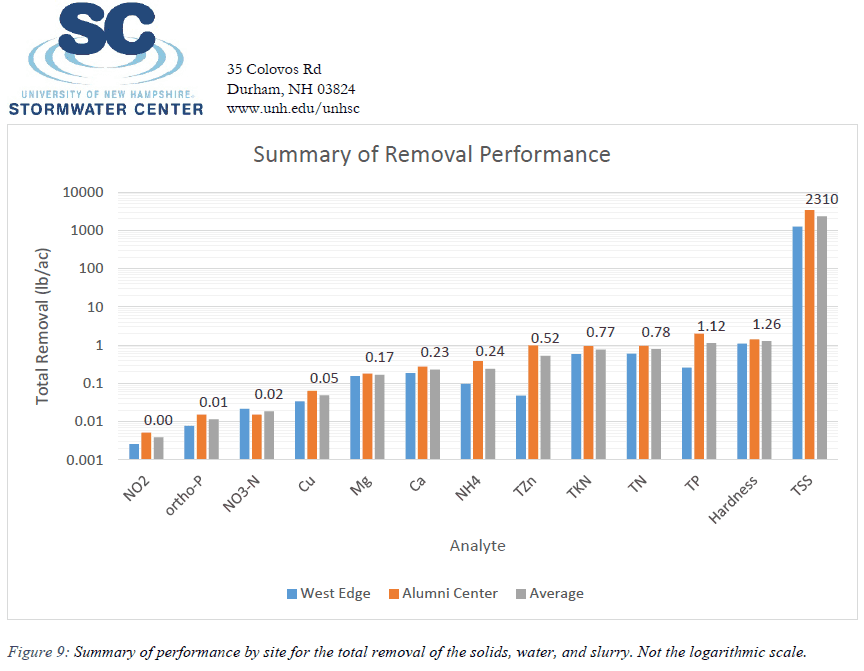

For a closer look at what you are pulling from your pervious and non-pervious surfaces, in 2019, the University of New Hampshire Stormwater Center analyzed the material recovered from two pervious surfaces during percolation recovery operations. The chart below summarizes the analysis of the material recovered in terms of pounds per acre. (note the logarithmic scale). The complete study can be accessed here: University of New Hampshire Stormwater Center Tests Pervious Pavement with Triverus at Durham, NH Campus

Does the Type of Dirt on a Road Vary By Location?

Depending on your location and application, the mix of material and pollutants recovered will vary. Cleaning western roadways will yield considerable amounts of copper while the same activity in the East tend not to return as much copper. Industrial sites or roadways near them will be loaded with more heavy metals contingent on the local industry involved.

Research has also shown that the tire preservative 6PPD is ubiquitous and deposited on roadways during the tire wear process. 6PPD is setting off alarm bells in the Pacific Northwest with studies linking it to high mortality rates in Coho Salmon.

High-Pressure wash with simultaneous recovery can be a key tool in removing all these pollutants from any hard surface. Using this cleaning method on pervious pavements has the added benefit of retaining and restoring percolation rates to keep stormwater outflows to a minimum.

Jumpstart solutions to your pervious maintenance and general pollution problems with Triverus. Get in touch with us today.